To keep your drive system running smoothly, regularly clean and lubricate your chain, check tension, and inspect for wear or damage. For belt drives, visually inspect for cracks or missing teeth, keep them clean, and guarantee proper tension. Shaft drives require regular gear oil changes and leak checks. Each type has unique maintenance needs, so staying consistent helps extend their life and performance. Keep going to discover expert tips for safe, reliable operation of all drive types.

Key Takeaways

- Regularly inspect and clean the drive components to prevent dirt buildup and wear.

- Lubricate chains and check tension frequently; belts and shaft systems require visual inspections and proper adjustments.

- Replace worn sprockets, chains, or belts promptly to ensure safety and optimal performance.

- Change gear oil in shaft drives as recommended to avoid gear damage and maintain smooth operation.

- Protect drives from excessive heat, sharp objects, and environmental factors to extend lifespan and reliability.

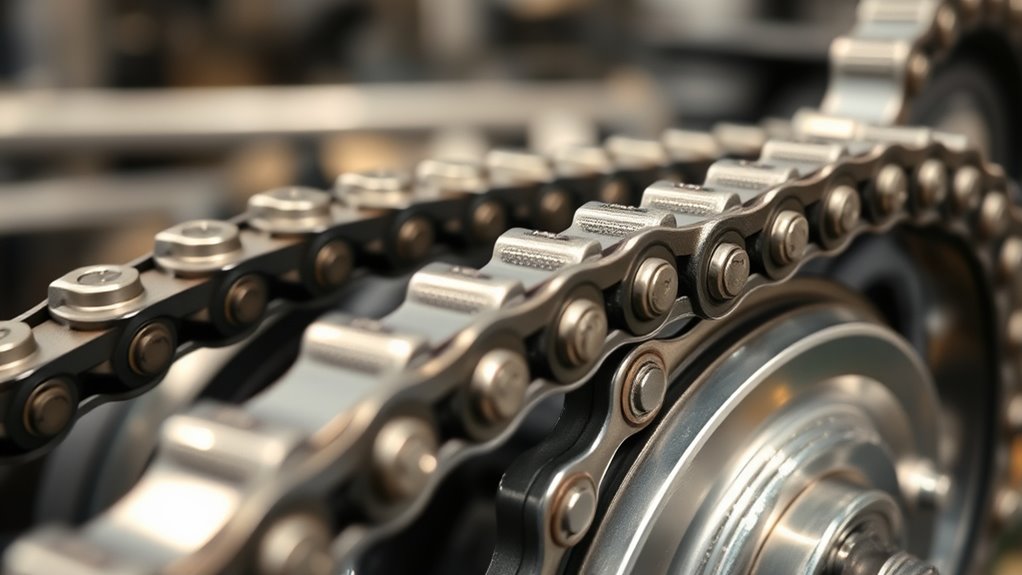

Essential Maintenance Tasks for Chain Drives

To keep your chain drive performing smoothly and prevent premature wear, regular maintenance is essential. Start by cleaning your chain frequently to remove dirt, grease, and debris that can accelerate corrosion and wear. Use a suitable chain degreaser and a soft brush to scrub away grime, then rinse with water and dry thoroughly. Next, lubricate the chain with high-quality chain oil or lubricant designed for your motorcycle’s conditions; this reduces friction and prevents rust. Check the tension regularly—if it’s too tight or loose, it can cause damage. Adjust the chain slack according to the manufacturer’s specifications. Finally, inspect your chain and sprockets for signs of wear, rust, or stiff links, replacing parts promptly to avoid breakdowns and ensure smooth power transfer. Additionally, understanding the importance of proper air purifier maintenance can help maintain a clean environment around your work area, preventing dust and allergens from affecting your motorcycle components. Regularly inspecting your drive components ensures early detection of issues that could lead to more significant problems. Incorporating proper lubrication techniques can significantly extend the lifespan of your chain and sprockets, reducing overall maintenance costs. Moreover, staying informed about Waterpark amenities can enhance your overall experience if you plan to visit related accommodations. Being aware of safety guidelines for chain maintenance can also help prevent accidents and injuries during servicing.

Upkeep Practices for Belt Drives

Maintaining your belt drive involves straightforward upkeep routines that keep it running smoothly and extend its lifespan. Regular visual inspections are key; look for cracks, missing teeth, or signs of wear. Clean the belt with warm, soapy water and a soft brush to remove dirt and debris—no lubrication needed. Although less frequent than chains, belt tension adjustments are important to prevent slipping and uneven wear. Proper tension ensures efficient power transfer and prolongs belt life. Additionally, avoid exposing the belt to sharp objects or excessive heat, which can cause damage. Regular calibration can also improve system performance and overall system health. Research indicates that sound vibrations can influence cellular regeneration and overall health, so keeping your system free of vibrations can contribute to its longevity. Maintaining proper system alignment is crucial for even wear and optimal operation. Regularly inspecting for signs of wear and tear helps catch issues early before they lead to costly repairs. Following these simple practices helps maximize the lifespan of your belt drive, ensures smooth operation, and prevents costly repairs. Regular checks and gentle cleaning are your best defense against premature belt failure.

Caring for Shaft Drive Systems

Caring for shaft drive systems involves keeping the gear oil fresh and at the right level to guarantee smooth operation. Regularly check the oil level and top it up with the manufacturer-recommended hypoid gear oil. Change the gear oil every 12,000 to 24,000 miles or as specified in your motorcycle’s manual to prevent gear wear and ensure quiet, reliable performance. Since shaft drives are enclosed, they’re protected from dirt, water, and debris, reducing cleaning needs. However, inspect for leaks or unusual noises during routine maintenance. Avoid neglecting oil changes, as degraded oil can cause gear damage. Proper care maximizes the lifespan of your shaft drive system, ensuring smooth power delivery and minimizing costly repairs. Additionally, understanding security systems can help you better grasp the importance of regular maintenance practices. Regular inspections of lubrication levels are essential to prevent gear failure and maintain optimal performance. Paying attention to enclosed drive systems helps protect critical components from environmental damage and extends service life.

Comparing Efficiency and Longevity of Drive Types

When comparing drive types, efficiency and longevity play crucial roles in determining which system best suits your riding needs. Belt drives excel in efficiency, needing less energy to operate, which boosts fuel economy and delivers a smoother, quieter ride. low maintenance requirements make belt drives a popular choice for many riders, as they require minimal adjustments and are less prone to failure. Additionally, their simple design contributes to easier installation and servicing. Belts also tend to resist environmental factors, which helps maintain performance over time. Chains are effective but less efficient, especially with wear, requiring frequent maintenance to prevent power loss. Proper lubrication and tension adjustments are essential to maintain optimal performance. Shaft drives rank lowest in efficiency due to heavier components and drivetrain losses, but they offer durability and low maintenance, often lasting a lifetime. Consider these points: belt drives are also known for longer service life, making them a reliable option for various riding conditions. Choosing depends on your priorities for performance, maintenance, and longevity.

Practical Tips to Ensure Safe and Reliable Operation

Ensuring safe and reliable operation of your motorcycle’s drive system starts with regular inspections and proper maintenance practices. For chain drives, clean and lubricate the chain frequently, and check tension to prevent slack or tightness. Replace worn sprockets and chains on schedule, typically every 30,000 to 50,000 miles. Regular drive system inspections can help identify issues early before they lead to bigger problems. Proper lubrication techniques for chains are essential for reducing wear and prolonging component life. Using the correct type of lubricant tailored for motorcycle chains can significantly improve durability. Belt drives need periodic visual checks for cracks or missing teeth and gentle cleaning with soap and water—no lubrication required. Adjust belt tension as needed to prevent slipping. Shaft drives require minimal attention but benefit from regular gear oil changes using recommended hypoid gear oil. Always inspect for damage or unusual noises, and address issues promptly. Following these simple steps helps ensure your drive system remains safe, efficient, and dependable during every ride. Incorporating local automation can also assist in monitoring and maintaining your motorcycle’s drive components more effectively through connected sensors and alerts.

Frequently Asked Questions

How Often Should I Replace My Motorcycle Chain, Belt, or Shaft Drive?

You should replace your motorcycle drive system based on its type. For chains, expect to replace them every 30,000 to 50,000 miles, depending on maintenance and riding conditions. Belts usually last between 60,000 and 100,000 miles if well-maintained, but watch for cracks or fraying. Shaft drives often last the lifetime of your motorcycle with proper gear oil changes, making replacement rare unless major issues arise. Regular inspections are essential.

What Are Signs of Drive System Failure I Should Watch For?

You should watch for signs like unusual noises, vibrations, or a loss of smooth power transfer. If your drive system looks worn, cracked, or frayed, it’s time to check further. Slipping belts, excessive slack, or stiff links in a chain indicate problems. Also, any visible rust, leaks, or difficulty in tension adjustment can signal impending failure. Regular inspections help catch issues early and keep your ride safe.

Can I Switch Between Drive Types Without Major Modifications?

You can switch between drive types, but it usually requires major modifications to your motorcycle. You’ll need to change the rear wheel, swingarm, and possibly the frame or mounting points to accommodate different drive systems. Plus, adjusting the final drive ratio and guaranteeing proper alignment are vital. Consulting a professional mechanic or manufacturer guidelines is essential before attempting such a conversion to ensure safety and compatibility.

How Do Environmental Factors Affect Each Drive System’s Lifespan?

Environmental factors can substantially impact each drive system’s lifespan. Dirt, water, and debris accelerate wear on chains, causing rust and stretching. Harsh weather and debris can crack or fray belts, shortening their life. Dirt, water, and grit can cause gear corrosion and damage within shaft drives, despite their protected design. Regular cleaning, inspection, and proper maintenance help shield each system from these elements, extending their durability and performance.

Are There Specific Tools Recommended for Maintaining Each Drive Type?

You need specific tools for each drive type. For chains, grab a chain breaker, a chain roller, and a good chain lubricant; a torque wrench helps with tension adjustments. For belts, use a belt tension gauge, soft brushes for cleaning, and inspect with a flashlight. Shaft drives require gear oil, a drain pan, and basic socket tools for oil changes. Proper tools make maintenance easier and guarantee your drive system stays in top shape.

Conclusion

No matter which drive system you choose, regular maintenance keeps your equipment running smoothly like a well-oiled machine. Stay vigilant with inspections, lubrication, and timely adjustments to prevent unexpected breakdowns. Think of your drive system as the heartbeat of your machinery—keep it healthy, and it’ll beat steadily for years to come. With proper care, you’ll guarantee efficiency and longevity, turning routine upkeep into a symphony of reliable performance.