To synchronize multiple carburetors on your classic multi-cylinder bike, you’ll need vacuum gauges to measure airflow consistency. Warm up the engine, then adjust the throttle linkages or cables so all gauges display similar readings at idle. Fine-tune the mixture screws for balanced airflow and responsiveness. Keep inspecting the gauges during revving to guarantee stability. Proper synchronization boosts engine smoothness, power, and fuel efficiency—so if you keep going, you’ll discover detailed steps to master the process.

Key Takeaways

- Warm up the engine and connect vacuum gauges to each carburetor’s ports before starting adjustments.

- Use vacuum gauges to compare readings at idle, ensuring all carburetors have equal vacuum levels.

- Adjust throttle linkages and screws to synchronize vacuum readings, promoting balanced airflow.

- Fine-tune mixture screws and throttle response to maintain steady, synchronized gauge readings during revving.

- Regularly recheck and adjust carburetors to maintain optimal performance and engine longevity.

Synchronizing multiple carburetors is essential for ensuring your engine runs smoothly and efficiently. When you have a classic multi-cylinder bike, each carburetor must work in harmony to deliver the right amount of fuel and air mixture to each cylinder. If they’re out of sync, your engine can run unevenly, stall, or waste fuel. The process of carburetor balancing involves adjusting the individual carburetors so they deliver equal airflow, which is crucial for optimal performance. Throttle synchronization, on the other hand, ensures that when you twist the throttle, all carburetors respond uniformly, opening at the same rate. Both steps are vital to keep your engine running at peak efficiency and to prevent uneven wear or poor fuel economy.

Synchronizing carburetors ensures smooth, efficient engine performance and prevents uneven wear or poor fuel economy.

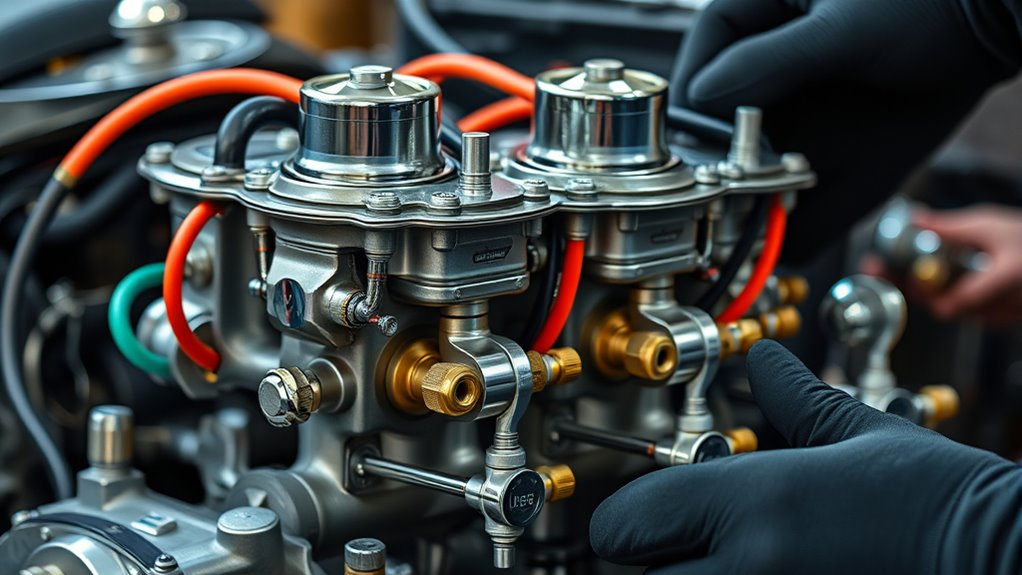

To begin, you’ll need a few tools: a set of synchronization gauges, usually vacuum gauges, and basic hand tools for adjustments. Start by warming up your engine to its normal operating temperature. This ensures that all components are working as they should be, giving you accurate readings. Once warm, locate the throttle cables and ensure they are adjusted evenly and have the same free play. This prevents any initial discrepancies that could skew your synchronization process. Now, connect your gauges to each carburetor’s vacuum ports. With the engine idling, you’ll see the readings—these indicate how much airflow each carburetor is supplying.

Next, you want to perform throttle synchronization. Carefully adjust the throttle linkages or cables so that all gauges read the same vacuum level. If one gauge shows higher vacuum, that carburetor is drawing less air, meaning it’s too rich or not opening fully. Conversely, a lower vacuum means it’s letting in more air. Fine-tune each carburetor’s throttle screw or linkage until all gauges match perfectly. This step ensures synchronized throttle response, so when you twist the throttle, all carburetors open simultaneously, providing smooth acceleration. Achieving proper airflow distribution is critical for maintaining engine performance and avoiding uneven wear.

After you’ve achieved throttle synchronization, move on to carburetor balancing. This involves adjusting the mixture screws or balancing valves to equalize airflow even further. Sometimes, this step requires a little trial and error, tweaking each screw slightly and watching the gauges. Your goal is to get each cylinder to receive the same mixture, which leads to smoother idling, better throttle response, and improved fuel economy. Once everything is balanced, rev the engine gently and observe the gauges. They should remain steady and in sync, confirming your carburetors are well synchronized.

Frequently Asked Questions

Can I Synchronize Carburetors Without Special Tools?

Yes, you can synchronize carburetors without special tools by using basic synchronization techniques. Start with carburetor basics like adjusting idle speed screws and throttle linkages. Then, listen for uneven engine sounds or rough idling, which indicates imbalance. You can use a simple homemade manometer or a vacuum gauge made from clear tubing to compare vacuum levels. While specialized tools are ideal, these methods help you achieve decent synchronization.

How Often Should I Synchronize My Carburetors?

You should synchronize your carburetors whenever you notice rough idling, poor acceleration, or uneven engine performance. Regularly, it’s a good idea to guarantee this after carburetor cleaning or tuning procedures, which can affect airflow balance. Typically, every 3,000 to 5,000 miles or once a year works well. Proper synchronization ensures smooth running, better fuel efficiency, and less engine wear, keeping your bike in top shape.

What Are Signs of Poorly Synchronized Carburetors?

Think of your engine as a choir; if one singer’s off-key, the harmony suffers. Signs of poorly synchronized carburetors include carburetor imbalance, causing uneven idling and rough running. You might also notice engine hesitation during acceleration, or a loss of power. If these symptoms appear, it’s a clear sign your carburetors need syncing to restore smooth, balanced performance and prevent further engine issues.

Is Synchronization Necessary After Every Ride?

No, you don’t need to synchronize your carburetors after every ride. Regular carburetor maintenance, like checking for proper synchronization, helps guarantee ideal engine performance. You should only re-sync if you notice rough idling, poor acceleration, or uneven power delivery. Frequent checks keep your bike running smoothly and prevent issues caused by misaligned carbs. So, unless symptoms appear, daily synchronization isn’t necessary, but routine maintenance is always recommended for peak engine performance.

Can Improper Sync Damage Engine Components?

Think of your engine as a finely tuned orchestra—improper sync can hit discordant notes, risking damage. Yes, poor synchronization can harm engine components over time by causing uneven wear, reduced fuel efficiency, and increased exhaust emissions. Misaligned carburetors strain pistons and valves, leading to costly repairs. Stay vigilant and keep your carburetors properly synchronized to preserve your engine’s health, efficiency, and environmental friendliness.

Conclusion

Now that you’ve synchronized your carburetors, your bike breathes better, boosting both balance and brilliance. With a steady hand and a sharp ear, you’ve tuned the tiny turbines to work in perfect tandem. The smooth symphony of synchronized cylinders transforms your ride into a seamless, sizzling streak across the street. Keep the harmony high and the engine enthusiastic — because a well-wound machine makes every mile more magical and memorable.