Blueprinting an engine involves precise measurement, machining, and assembly to maximize performance, efficiency, and reliability. You focus on critical components like pistons, cylinders, and the crankshaft, ensuring they fit perfectly within tight tolerances. Proper balancing and valve timing improve power, reduce emissions, and extend engine life. This old-school approach combines attention to detail and skill to enhance your engine’s potential. Keep going to discover how every step boosts your engine’s ultimate performance.

Key Takeaways

- Measure and machine engine components to tight tolerances for perfect fit and reduced mechanical losses.

- Balance rotating assemblies like the crankshaft and pistons to ensure smooth engine operation.

- Precisely set valve timing and clearance to optimize airflow and combustion efficiency.

- Use meticulous assembly techniques to align components, prevent wear, and enhance reliability.

- Focus on optimizing compression ratios and reducing internal friction for maximum power and fuel economy.

Blueprinting an engine is a precise process that involves optimizing each component to maximize performance and efficiency. When you undertake this meticulous task, you’re not just making your engine run; you’re fine-tuning it for superior results. One of the key benefits of blueprinting is improving fuel efficiency. By ensuring each part is machined and assembled to exact specifications, you reduce internal friction and mechanical losses. This means your engine doesn’t waste energy fighting against unnecessary resistance, which directly translates to better mileage. Additionally, a carefully balanced and precisely assembled engine burns fuel more completely, leading to more power output from less fuel. This efficiency not only saves you money at the pump but also helps in reducing harmful emissions, making your vehicle more environmentally friendly.

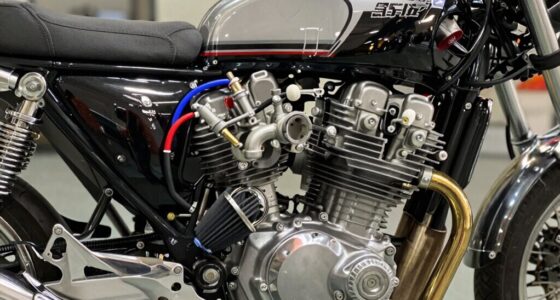

When you start blueprinting, you’ll need to focus on critical components like pistons, cylinders, and the crankshaft. You’ll measure and machine these parts to tight tolerances, ensuring they fit perfectly. This precision prevents issues like piston slap or uneven wear, which can cause power loss and increase emissions. Properly matched components promote a more complete combustion process, which enhances fuel efficiency and cuts down on pollutants released into the atmosphere. It’s about creating an engine that runs smoothly and predictably, with optimal compression ratios and balanced rotating assemblies. The result is not just more power but cleaner operation.

Another aspect you should pay attention to is valve timing and clearance. Adjusting these parameters accurately ensures the engine breathes efficiently, which is vital for both performance and emissions reduction. When the valves open and close at precisely the right moments, the engine maintains a better air-fuel mixture, reducing unburned hydrocarbons and carbon monoxide. These adjustments contribute to meeting environmental standards while also making your engine more responsive and powerful. The process might involve degreeing the camshaft and carefully setting lash, but the payoff is a finely tuned engine that performs at its best. Moreover, understanding engine durability can help you select the right materials and components to ensure your engine remains reliable over time.

Ultimately, blueprinting isn’t just about adding horsepower; it’s about creating a balanced, efficient machine. You get the benefits of improved fuel economy and lowered emissions, all while enjoying a more reliable engine. By meticulously measuring, machining, and assembling every part to exact specifications, you’re ensuring each component works harmoniously. This old-school approach might be labor-intensive, but it rewards you with an engine that’s optimized for performance, efficiency, and environmental friendliness—truly the best of all worlds.

Frequently Asked Questions

What Tools Are Essential for Engine Blueprinting?

You’ll need vital tools like a cylinder inspection gauge to check for wear and proper sizing, making certain your engine’s cylinders are perfectly round and true. A valve alignment tool is essential for setting the valves to the correct angles, optimizing airflow and performance. Additionally, precision measuring instruments like micrometers and dial indicators help verify tolerances. These tools guarantee your engine is blueprint-ready, delivering maximum power and efficiency.

How Long Does a Typical Blueprinting Process Take?

The blueprinting process usually takes about 10 to 20 hours, depending on your engine’s condition. You’ll spend time on engine block modifications, guaranteeing precise cylinder bore measurements, and adjusting piston clearance for peak performance. Careful attention to detail during these steps ensures your engine runs smoothly and maximizes power. Rushing can cause issues, so take your time to measure, modify, and verify each component thoroughly.

Can Blueprinting Be Done on Any Engine Type?

You can blueprint many engine types, but it’s not universal. About 60% of vehicle engines are suitable for blueprinting, yet some models face limitations due to design complexity or missing specifications. Engine compatibility depends on factors like block design and parts availability. Keep in mind, blueprinting limitations may prevent certain engines from achieving maximum performance gains, so always evaluate if your specific engine can benefit before starting the process.

What Are the Cost Implications of Engine Blueprinting?

The cost analysis of engine blueprinting varies based on your engine type and the extent of modifications. Budget considerations play a big role, as professional services can range from a few hundred to several thousand dollars. You might save by doing some work yourself, but high-quality results usually require expert input. Weigh your performance goals against your budget to decide if blueprinting fits your project.

How Often Should an Engine Be Blueprinted for Optimal Performance?

You should blueprint your engine every 15,000 to 20,000 miles to maintain peak performance. Regular blueprinting enhances engine longevity by ensuring parts stay precisely tuned, which improves tuning precision. This proactive approach prevents wear and tear, keeping your engine running smoothly. If you notice performance drops or unusual noises, consider blueprinting sooner. Consistent maintenance like this maximizes power output and extends your engine’s lifespan.

Conclusion

Blueprinting your engine is like tuning a fine instrument—you get every part perfectly aligned for peak performance. By carefully inspecting, measuring, and adjusting, you reveal hidden power and reliability. It’s a hands-on approach that rewards patience and precision. Just as a master craftsman molds their work, you craft a smoother, more efficient engine. Embrace the old-school way, and you’ll enjoy the thrill of a finely tuned machine that runs like a well-oiled racecar.