To maintain your classic bike’s fuel system with ethanol-blended gas, regularly inspect and replace rubber and plastic parts with ethanol-resistant materials, like Viton or Teflon. Use fuel stabilizers designed for ethanol blends, keep tanks full to reduce moisture buildup, and consider switching to ethanol-free fuel if possible. Routinely clean your carburetor and fuel lines to prevent varnish and corrosion. Staying proactive will help extend your bike’s performance and reliability—learn more about safeguarding your vintage ride.

Key Takeaways

- Use ethanol-free gasoline whenever possible to prevent corrosion and water absorption in fuel systems.

- Regularly inspect and replace rubber and plastic fuel components with ethanol-resistant materials.

- Add fuel stabilizers designed for ethanol blends before storage to maintain fuel stability and prevent varnish buildup.

- Keep fuel tanks full and sealed to minimize moisture ingress and phase separation.

- Perform routine cleaning and maintenance of carburetors and fuel filters to remove deposits and ensure proper flow.

Understanding Ethanol’s Impact on Classic Fuel Systems

Ethanol’s increasing use in fuels considerably affects the integrity and performance of classic motorcycle fuel systems. You’ll notice that ethanol burns hotter than pure gasoline, which raises engine and exhaust temperatures, speeding up the wear on hoses, gaskets, and emission hardware. It also absorbs water from the air, causing phase separation in your fuel tank—this leads to corrosion and poor engine performance once water levels exceed 11%. Metal parts, especially in older bikes with rubber and plastic components, are vulnerable to corrosion from ethanol’s chemical properties. Additionally, ethanol lowers the fuel’s energy content, decreasing power and fuel economy, and can cause varnish buildup in carburetors. Understanding these effects helps you take the right steps to protect and maintain your classic motorcycle. European cloud innovation offers sustainable solutions that can support advanced fuel management systems to monitor ethanol content and prevent damage. Being aware of ethanol-induced corrosion and implementing proper maintenance practices are essential for longevity. Regular inspections and corrosion prevention techniques can significantly extend the lifespan of your fuel system components.

Recognizing Signs of Ethanol-Related Damage

Since ethanol can cause subtle but serious damage to your motorcycle’s fuel system, recognizing early signs is essential for preventing costly repairs. Look out for symptoms like fuel leaks, corrosion, or softening of rubber parts. Engine misfires, hard starting, or reduced power may indicate water or varnish buildup. You might also notice sediment or debris in the fuel filter. Regularly inspect your fuel lines, tank, and carburetor components for signs of deterioration. Here’s a quick reference:

| Sign of Damage | Potential Cause |

|---|---|

| Fuel leaks | Cracked or softened hoses |

| Rust spots | Water-induced corrosion |

| Hard starts | Water phase separation or varnish |

| Reduced performance | Deposits clogging carburetor |

| Engine misfire | Water contamination or degraded fuel |

Early detection helps you address issues before they escalate. Additionally, understanding fuel system maintenance can help prolong the life of your classic bike’s components.

Choosing the Right Fuel for Your Vintage Motorcycle

To keep your vintage motorcycle running smoothly, it’s best to stick to fuels with lower ethanol content, ideally E10 or less. Whenever possible, choose ethanol-free gasoline to avoid the risks associated with ethanol-blended fuels. Making this choice helps protect your engine and fuel system from corrosion and performance issues. Additionally, regularly inspecting and cleaning your fuel system components can prevent fuel system corrosion caused by ethanol’s hygroscopic properties. Using natural pools or environmentally friendly options can also minimize chemical exposure that may accelerate corrosion in fuel systems. Being aware of global chaos events, like major outages, can also help you prepare for supply disruptions of certain fuel types. Understanding how ethanol blends interact with different engine materials can further improve your maintenance routine. Incorporating seasonal fuel testing can assist in identifying fuel issues before they cause engine problems.

Ethanol Content Limits

Choosing the right fuel for your vintage motorcycle is essential to prevent damage and guarantee peak performance. Limit ethanol content to avoid issues like corrosion, water absorption, and power loss. Stick to fuels with no more than 10% ethanol (E10), as higher levels like E15 or E85 can cause severe damage to fuel systems and engine components. Many regions restrict ethanol levels in premium or specialty fuels, so check local fuel labels carefully. If possible, opt for ethanol-free gasoline, especially during long storage periods or frequent use in older bikes. By controlling ethanol limits, you reduce water phase separation, corrosion risks, and performance drops, helping you maintain your motorcycle’s reliability and longevity. Always verify fuel labels and seek high-quality, low-ethanol or ethanol-free options.

Opting for Ethanol-Free Fuel

Opting for ethanol-free fuel can substantially reduce the risk of corrosion, phase separation, and performance issues in your vintage motorcycle’s fuel system. By choosing pure gasoline, you avoid water absorption, varnish buildup, and deposits caused by ethanol. Here are three benefits:

- Prevents corrosion—eliminates water-induced rust and deterioration of metal parts. Using ethanol-free fuel also minimizes the formation of corrosive byproducts that can accelerate metal degradation. Regularly inspecting and maintaining your fuel system further helps prevent corrosion and prolong the lifespan of engine components.

- Maintains fuel stability—reduces phase separation and gelling during storage, especially when combined with proper fuel storage practices. Ensuring your fuel is stored in a sealed, cool, and dry environment can significantly improve its longevity.

- Improves performance—ensures consistent fuel combustion, better throttle response, and fuel economy. Using high-quality fuel along with proper carburetor tuning optimizes engine efficiency and smooth operation.

Using ethanol-free fuel helps your classic bike run smoother, last longer, and minimizes costly repairs. Although it may cost a bit more, the longevity and reliability it offers make it a smart investment for vintage motorcycle owners. Safe fuel storage practices can further enhance the benefits of using ethanol-free fuel and protect your motorcycle’s fuel system during long periods of inactivity.

Effective Storage Techniques to Minimize Ethanol Effects

Proper storage techniques are essential for minimizing the damaging effects of ethanol on your motorcycle’s fuel system. To reduce water absorption, keep your tank as full as possible—this limits air space where moisture can condense. Use a high-quality fuel stabilizer designed for ethanol blends before storing your bike, which helps prevent phase separation and corrosion. Store your motorcycle in a cool, dry place, away from temperature fluctuations that promote condensation. Consider installing a vented fuel cap or sealing your tank tightly to prevent humidity from entering. If storing for an extended period, periodically start the engine or run the bike to circulate the fuel and prevent varnish buildup. Incorporating Indigenous wellness essentials into your routine can promote overall mental clarity and resilience, which is beneficial during periods of maintenance or environmental stress. These practices help maintain fuel integrity and protect your motorcycle’s components from ethanol-related damage.

Using Additives and Stabilizers for Ethanol Blends

Using additives and stabilizers is essential for protecting your motorcycle’s fuel system when running on ethanol-blended fuels. They help prevent water absorption, corrosion, and varnish buildup that ethanol can cause. To get the most out of these products, consider these options:

- Use fuel stabilizers designed specifically for ethanol blends to keep fuel fresh during storage and reduce phase separation.

- Add corrosion inhibitors to protect metal parts, especially in older tanks and carburetors vulnerable to rust.

- Incorporate fuel system cleaners periodically to remove varnish, deposits, and gum that ethanol can promote.

Applying these additives correctly ensures smoother engine performance, longer-lasting fuel components, and fewer maintenance headaches. Always follow manufacturer instructions for dosage and frequency to maximize their effectiveness.

Maintaining and Rebuilding Carburetors in Ethanol Environments

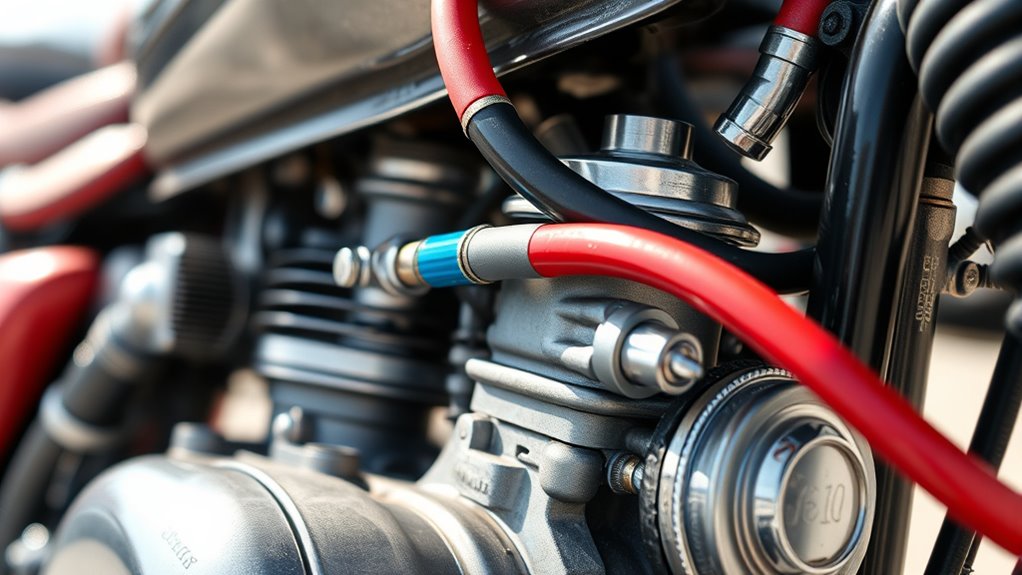

To keep your carburetor running smoothly in ethanol environments, you need to focus on cleaning deposits and varnish buildup regularly. Using ethanol-resistant parts, like gaskets and fuel lines, can also prevent corrosion and leaks. Staying proactive with maintenance ensures your engine stays reliable and performs at its best. Additionally, understanding fuel system compatibility can help you select the right components that withstand ethanol’s effects over time.

Cleaning Carburetor Deposits

Ethanol-laced fuels can cause carburetors to develop stubborn varnish buildup and sticky deposits that impair fuel flow and engine performance. To keep your carburetor running smoothly, you need to clean these deposits regularly. Incorporate practical tools like carb cleaner and brushes to effectively remove buildup and maintain optimal function.

- Start by removing the carburetor and soaking it in a specialized carb cleaner to dissolve varnish and gunk. This process helps prevent the build-up of deposits that can compromise the carburetor’s efficiency.

- Use a soft brush or compressed air to scrub out jets, passages, and float bowls, ensuring no debris remains.

- Reassemble the carb carefully, checking for any clogged jets or stuck float valves that could cause fuel flow issues.

Regular cleaning prevents deposits from hardening and causing engine misfires, hard starts, or poor throttle response. Staying on top of carburetor maintenance ensures your classic bike runs reliably in ethanol environments.

Using Ethanol-Resistant Parts

Are your carburetor components prepared to withstand the corrosive effects of ethanol-blended fuels? Upgrading to ethanol-resistant parts is essential for reliable performance. Replace rubber and plastic components with materials specifically designed for ethanol compatibility, such as Viton or Teflon seals and gaskets. Use stainless steel or brass jets and screws to prevent corrosion and deterioration. Consider installing fuel lines made from ethanol-resistant synthetic rubber or PTFE. These materials resist swelling, cracking, and corrosion caused by water absorption and chemical reactions. Regularly inspect and replace worn parts with compatible alternatives to maintain proper fuel flow. Investing in ethanol-resistant components helps prevent varnish buildup, blockages, and leaks, ensuring your classic bike runs smoothly and reduces costly repairs caused by ethanol-related damage. Incorporating proper power tools and equipment during maintenance can streamline these updates and improve overall safety and efficiency. Additionally, utilizing ethanol test kits can help monitor fuel quality and prevent potential engine issues. Understanding material compatibility is vital when selecting replacement parts to ensure long-term durability in ethanol environments, especially given the increasing reliance on digital payment solutions in modern commerce, which highlights the importance of using reliable and corrosion-resistant components. Moreover, staying informed about best maintenance practices can extend the lifespan of your bike’s fuel system and improve performance.

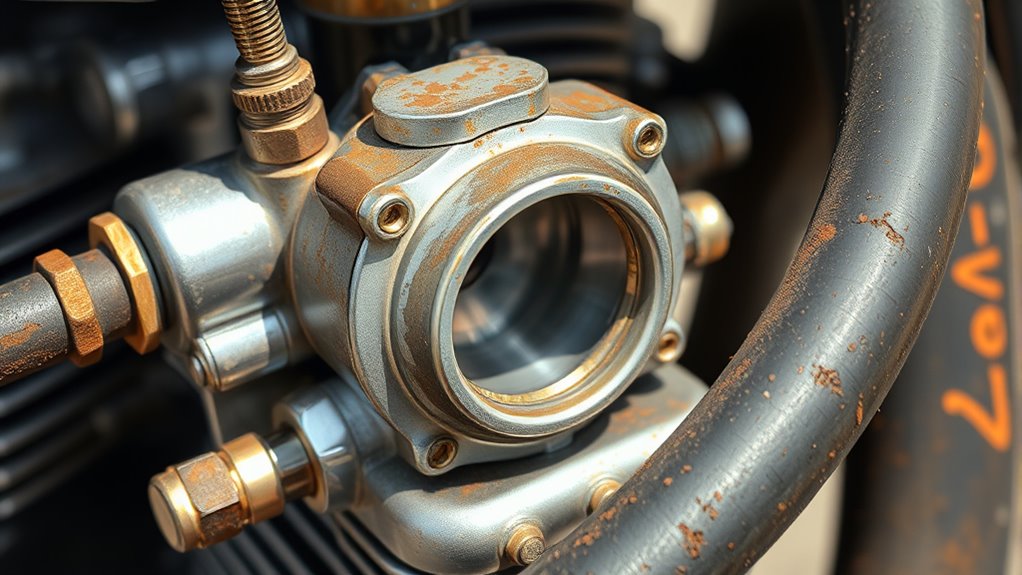

Replacing Rubber and Plastic Components With Ethanol-Resistant Materials

Since ethanol can cause rubber and plastic components in your motorcycle’s fuel system to degrade, upgrading to ethanol-resistant materials is essential for maintaining reliable performance. You should prioritize replacing vulnerable parts with compatible alternatives to prevent leaks, clogs, and failures. Additionally, choosing proper storage techniques can help extend the lifespan of these components and ensure optimal operation. Here are three key upgrades:

- Use ethanol-resistant fuel hoses made from materials like Viton or Teflon, which resist ethanol’s corrosive effects.

- Replace rubber gaskets and seals with ethanol-compatible silicone or fluorocarbon versions to ensure a tight, durable seal.

- Swap out plastic fuel filters for ones constructed from ethanol-resistant plastics or metal to avoid swelling and deterioration.

These replacements help safeguard your fuel system and keep your classic bike running smoothly.

Monitoring Engine Performance and Fuel Economy Changes

Monitoring your motorcycle’s engine performance and fuel economy is essential to detect early signs of ethanol-related issues. You should pay attention to changes like sluggish acceleration, rough idling, or misfires, which may indicate fuel system problems. Keep track of fuel economy; a sudden drop suggests water contamination or incomplete combustion. Regularly inspect for leaks, corrosion, and carbon deposits. The following table highlights key indicators:

| Symptom | Possible Cause | Action |

|---|---|---|

| Reduced fuel efficiency | Water phase separation or deposits | Clean carburetor, check tank |

| Engine misfires | Varnish buildup or water in fuel | Use fuel stabilizer, replace parts |

| Hard starting | Fuel line clog or water in tank | Drain tank, replace fuel lines |

Additionally, using the right oil for your fuel system and engine components can help reduce wear caused by ethanol blends. Consistent monitoring helps you catch issues early, minimizing damage and maintaining performance. Proper maintenance practices ensure the longevity and reliability of your motorcycle’s fuel system.

Seasonal Maintenance Tips for Long-Term Storage

To guarantee your classic motorcycle stays in top condition during long-term storage, proper seasonal maintenance is essential. Ethanol fuels can cause water absorption, phase separation, and corrosion if not managed carefully. To protect your bike:

- Fill the tank completely and add a fuel stabilizer formulated for ethanol blends to prevent water buildup and gelling.

- Disconnect the battery and keep it on a trickle charger to avoid sulfation and discharge.

- Cover the motorcycle with a breathable cover in a dry, ventilated area to reduce moisture and condensation.

Additionally, consider draining the carburetor and inspecting rubber hoses for signs of deterioration. Regularly check for leaks or corrosion before restarting your bike. Proper preparation guarantees reliable performance when you ride again.

Best Practices for Regular Fuel System Inspections

You should regularly check your fuel system for signs of corrosion, like rust or staining, to catch problems early. Inspect your fuel lines for cracks, leaks, or soft spots that could compromise performance. Staying vigilant with these simple steps helps prevent costly repairs and keeps your motorcycle running smoothly.

Check for Corrosion Signs

Regularly inspecting your motorcycle’s fuel system is essential to catch corrosion early before it causes serious damage. Ethanol can accelerate rust and deterioration, especially in older parts. To stay ahead, check for these signs:

- Rust or discoloration around fittings, tank seams, or inside fuel lines, indicating water or moisture buildup.

- Corroded or pitted metal parts like the tank, carburetor, or fuel cap, which suggest ongoing rust issues.

- Leaking or hardened seals and gaskets, especially if they appear cracked or swollen, showing exposure to moisture and ethanol effects.

Perform these inspections routinely, especially after seasonal storage. Catching corrosion early prevents costly repairs and keeps your bike running smoothly. Stay vigilant and address issues as soon as you notice them.

Inspect Fuel Lines Regularly

Inspecting your fuel lines is a key step in maintaining your motorcycle’s fuel system, especially considering how ethanol can accelerate deterioration. Regular checks help you catch cracks, leaks, or softening in rubber hoses early, preventing fuel leaks or blockages. Look for signs of hardening, swelling, or discoloration, which indicate material breakdown. Ensure clamps are tight and secure, and that no fuel is seeping from connections. Ethanol’s moisture absorption can cause rust and corrosion inside metal lines, so inspect for any rust spots or buildup. Replace damaged or aged hoses with ethanol-resistant materials to avoid future issues. Frequent inspections keep your fuel system clean, safe, and running efficiently, reducing the risk of engine performance problems caused by compromised fuel lines.

Frequently Asked Questions

Can Ethanol-Blended Fuel Damage Modern Fuel Injection Systems?

Ethanol-blended fuels can damage modern fuel injection systems if you don’t take precautions. Ethanol causes corrosion of metal components, degrades rubber and plastic parts, and promotes varnish buildup in injectors. Water absorption can lead to phase separation, causing poor atomization and engine misfires. To protect your system, use ethanol-compatible parts, add fuel stabilizers, and avoid high ethanol blends like E15, especially during storage or prolonged use.

How Often Should I Clean or Rebuild My Carburetor With Ethanol Fuel?

You should clean or rebuild your carburetor at least once a riding season when using ethanol fuel. Ethanol’s sticky deposits and varnish buildup can clog carburetor components over time, causing poor performance and engine misfires. Regular maintenance prevents problems, preserves power, and prolongs the life of your classic bike. If you ride less frequently, consider more frequent inspections and cleanings to keep your engine running smoothly and reliably.

Are There Specific Ethanol-Free Fuels Recommended for Vintage Motorcycles?

Yes, you should look for ethanol-free premium fuels or racing fuels designed for vintage motorcycles. Brands like Sta-Bil, TruFuel, or Sunoco offer ethanol-free options that are ideal for preserving your bike’s fuel system and engine performance. Always check labels carefully to confirm ethanol content is zero. Using these fuels reduces corrosion, phase separation, and deposit buildup, helping your classic bike run smoothly and last longer.

What Are the Best Materials for Fuel Lines in Ethanol-Rich Environments?

You should choose fuel lines made from ethanol-resistant materials like fluoropolymer (such as Teflon), stainless steel, or ethanol-compatible rubber compounds. These materials resist corrosion and swelling caused by ethanol. Avoid regular rubber or plastic lines, which can degrade or crack over time. Regularly inspect your fuel lines for signs of wear or leaks, and replace them with ethanol-compatible options to guarantee your motorcycle’s fuel system remains dependable in ethanol-rich environments.

How Does Ethanol Affect Motorcycle Emissions and Compliance Regulations?

Ethanol increases motorcycle emissions by raising exhaust temperatures and promoting incomplete combustion, which can lead to higher levels of pollutants like carbon monoxide and unburned hydrocarbons. It also accelerates wear on emission control hardware, making it harder to meet strict regulations. To stay compliant, you should use ethanol-resistant parts, avoid high ethanol blends, and make sure your bike’s emission systems are properly maintained and functioning efficiently.

Conclusion

Did you know that ethanol-blended fuels can cause up to 50% more corrosion in classic fuel systems? Staying proactive with regular inspections and using ethanol-resistant parts can save you time and money. By understanding ethanol’s impact and applying proper maintenance techniques, you’ll keep your vintage motorcycle running smoothly for years to come. Don’t wait for problems to arise—take these steps now to protect your bike’s fuel system and enjoy reliable rides every time.