If your engine only runs on choke, start by checking for clogged carburetor passages, vacuum leaks, or air leaks in hoses and gaskets. Inspect the choke operation, clean the carb thoroughly, and make certain proper adjustment of mixture screws. Also, verify fuel delivery components like filters and pumps are working correctly. Addressing these issues often solves the problem, and if you keep exploring, you’ll find more tips to get your engine running smoothly without relying on the choke.

Key Takeaways

- Check for clogged carburetor passages or debris blocking fuel flow, causing the engine to run only with choke.

- Inspect for air leaks in intake hoses or gaskets, which can create a lean environment requiring choke for operation.

- Verify carburetor adjustments, especially mixture screws, to ensure proper fuel and air mixture at idle.

- Examine fuel delivery system components like filters and pumps for clogs or malfunctions limiting fuel supply.

- Clean and maintain the carburetor regularly to prevent varnish buildup and ensure smooth operation without choke dependence.

Common Causes of Choke-Dependent Running

One of the most common reasons your engine depends on the choke to run is because of a lean air-fuel mixture caused by clogged carburetor passages. Dirt, debris, or varnish buildup can block the small channels that deliver fuel, making it difficult for the engine to receive enough fuel during warm-up. Additionally, air leaks in the intake system, such as cracked gaskets or broken boots, introduce extra air, further leaning out the mixture. Incorrect carburetor adjustments, like misaligned mixture screws, can also cause a lean condition. Fuel delivery issues, such as clogged filters or weak pumps, reduce fuel flow, making the choke necessary to compensate temporarily. All these factors create a lean environment that relies heavily on choke for smooth operation.

Recognizing Symptoms of Carburetion Issues

If your engine stalls shortly after warming up, it’s a clear sign of carburetion trouble. You might also notice that the throttle feels unresponsive when you try to accelerate under load. Recognizing these symptoms early helps pinpoint issues like air leaks, clogged jets, or improper adjustments. Additionally, Free Floating phenomena can cause inconsistent carburetor performance, leading to engine running issues.

Idle Stalls After Warm-Up

Have you noticed your engine stalls shortly after warming up and running smoothly at first? This is a common sign of carburetion issues. You might find that your engine idles fine cold but quickly stalls once it reaches operating temperature. Often, this indicates a lean mixture caused by clogged jets, vacuum leaks, or incorrect adjustments. To understand the problem better, consider this table:

| Symptom | Possible Cause |

|---|---|

| Engine stalls after warm-up | Air leaks or lean mixture |

| Rough idle | Dirty or clogged jets |

| Unstable RPMs | Incorrect mixture settings |

| Engine bogs under load | Fuel delivery problems |

| Difficult restart | Fuel or vacuum leaks |

Addressing these issues requires inspecting gaskets, cleaning jets, and checking for leaks to restore smooth operation. Recognizing carburetion problems early can prevent further engine damage and improve overall performance. Additionally, performing regular carburetor maintenance can help identify issues before they cause stalls or rough running. Being aware of fuel system components and their proper functioning is essential for diagnosing these problems effectively. Proper tuning and inspection of the air-fuel mixture are critical for optimal engine performance and preventing stalls. Regularly checking for vacuum leaks can also help maintain smooth engine operation and prevent stalls.

Unresponsive Throttle Under Load

When your engine responds sluggishly or fails to accelerate properly under load, it often points to carburetion problems. You might notice it bogs down when you give it throttle, struggling to reach higher RPMs or losing power suddenly. This happens because the carburetor isn’t supplying enough fuel during increased demand, often due to clogged jets, dirty passages, or vacuum leaks. You may also feel a lack of responsiveness, with the engine feeling choked or starved for fuel. In some cases, the engine stalls or sputters when you try to accelerate under load. These symptoms signal that the carburetor isn’t delivering a proper mixture, and your first step should be inspecting for dirt, debris, or leaks that could be affecting fuel flow and mixture balance. Proper carburetor function is essential for consistent engine performance under varying loads, as it ensures the correct air-fuel mixture reaches the engine at all times. Additionally, understanding fuel delivery systems can help you diagnose underlying issues more effectively. Recognizing symptoms of clogging or leaks can lead to quicker troubleshooting and more reliable engine operation. Regular maintenance and carburetor cleaning can prevent these issues from developing into major problems.

Inspecting and Diagnosing Air Leaks and Vacuum Leaks

Are you noticing your engine stalls or runs rough even after warm-up? Air leaks or vacuum leaks could be the culprit. These leaks let in extra air, lean out the mixture, and make your engine rely on the choke. To diagnose, start by inspecting the intake system for cracks, torn gaskets, or loose clamps. Use a spray of carb cleaner or WD-40 around the intake and vacuum lines—if the engine revs or smooths out, you found a leak. Check these key points:

- Cracked intake boots or hoses

- Loose or torn gaskets

- Cracks around carburetor mounting

- Damaged or disconnected vacuum lines

Fixing these leaks restores proper air-fuel balance and reduces choke dependency, improving engine performance. Paying attention to engine troubleshooting techniques can help identify underlying issues more effectively. Additionally, understanding how air-fuel mixture impacts engine operation can lead to more precise repairs.

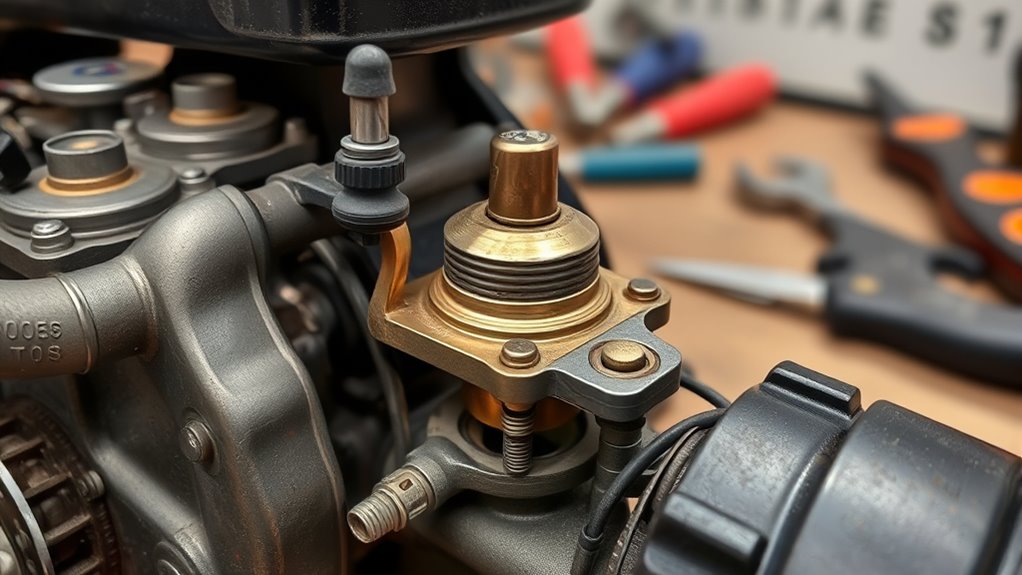

Cleaning and Adjusting the Carburetor for Optimal Performance

To guarantee your engine runs smoothly and minimizes choke reliance, cleaning and adjusting the carburetor is essential. Start by removing the carburetor and inspecting for dirt, varnish, or debris in the jets, passages, and bowl. Use carburetor cleaner and compressed air to clear clogs and ensure fuel flows freely. Pay close attention to the choke valve — it should move smoothly and close tightly when engaged. Once cleaned, reassemble the carburetor and adjust the mixture screws. Turn the idle screw clockwise to increase fuel or counterclockwise to lean the mixture, aiming for a stable, smooth idle. Make small adjustments, test, and repeat until the engine runs smoothly without choke. Proper tuning helps optimize performance, fuel efficiency, and reduces dependence on choke during startup. Additionally, understanding the importance of consistent visual and auditory cues can aid in diagnosing and maintaining optimal carburetor function. Regular inspection and prompt cleaning can prevent buildup that causes clogged jets, ensuring consistent engine response. Maintaining a clean air filter also plays a vital role in preventing dirt from entering the carburetor and affecting operation. Incorporating the use of filtration and pump protection measures can further enhance the longevity of your carburetor components. To further safeguard your engine, consider using fuel stabilizers, which can prevent varnish buildup and keep fuel system parts clean during periods of inactivity.

Ensuring Proper Fuel Delivery and System Components

Ensuring proper fuel delivery starts with inspecting the entire fuel system for any blockages or leaks. Check fuel filters for clogs, and replace them if dirty. Examine fuel lines and pumps for cracks, leaks, or restrictions, ensuring fuel flows freely. Confirm the fuel tank vent is clear to prevent vacuum buildup that hampers fuel flow. Make sure the carburetor’s fuel inlet is unobstructed and clean. Regular maintenance of these components can prevent issues related to toilet flushing mechanisms that rely on consistent fuel supply.

Preventive Steps to Maintain Carburetor Health

To keep your carburetor running smoothly, you should stick to a regular cleaning schedule and use fresh fuel. Clean the carburetor at least once a year or whenever you notice performance issues. Always fill with fresh fuel and add stabilizer to prevent gumming and clogging. Additionally, utilizing AI-powered tools can help you identify and troubleshoot common carburetion problems more efficiently. Proper piercing care and hygiene, especially avoiding irritants and monitoring for signs of infection, can also prolong the life of your carburetor by preventing debris buildup and corrosion. Incorporating sound healing science techniques to promote overall engine health and reduce stress on components can be a helpful preventative measure. Regular inspection of essential oils for maintenance can provide additional protection against corrosion and buildup, ensuring optimal performance.

Regular Cleaning Schedule

Regular cleaning of your carburetor is essential for maintaining ideal engine performance and preventing common issues like stalling or rough idle. By establishing a regular cleaning schedule, you minimize dirt, varnish, and debris buildup that can clog jets and passages. This proactive approach helps keep fuel flow consistent and prevents lean conditions that make you rely on the choke. You should clean your carburetor at least once a year or whenever you notice performance drops. Use carburetor cleaner to remove residue, and inspect components for damage. Regular maintenance helps extend your carburetor’s lifespan and ensures smooth operation. Additionally, understanding carburetion principles can aid in diagnosing and preventing issues before they escalate. Performing proper adjustments can optimize fuel mixture and improve engine performance. Remove and clean jets and passages regularly – Use fresh fuel and fuel stabilizer during storage – Check and replace gaskets and seals as needed – Keep air filters clean to prevent dirt from entering

Use Fresh Fuel Properly

Have you ever experienced engine trouble after using old or stale fuel? Using fresh fuel is essential for maintaining your carburetor’s health. Old fuel can gum up jets, passages, and float bowls, leading to clogged components and lean mixtures that cause your engine to run only on choke. Always fill your tank with fresh fuel, especially after long periods of storage. If you plan to store your equipment, add a fuel stabilizer to prevent gumming and oxidation. Before storage, run the engine briefly to circulate the stabilized fuel. Regularly draining and replacing old fuel reduces deposits and keeps the carburetor functioning smoothly. Proper fuel management not only improves performance but also extends the life of your carburetor and engine.

Frequently Asked Questions

How Do I Know if My Carburetor Needs Replacing?

You’ll know your carburetor needs replacing if cleaning and adjusting don’t fix issues like poor idle, stalling, or trouble restarting, even after checking for air leaks and clogged jets. Signs also include persistent fuel leaks, visible damage, or corrosion. If your engine still runs only with choke on despite troubleshooting, it’s time to contemplate replacing the carburetor to restore proper fuel and air mixture.

Can a Dirty Spark Plug Cause Engine Only to Run on Choke?

A dirty spark plug can cause your engine to only run on choke because it hampers proper ignition, leading to weak or inconsistent sparks. This makes it hard for the engine to fire correctly, especially once the choke is released. To fix this, clean or replace the spark plug, make certain proper gap, and check for signs of fouling. Doing so helps restore reliable ignition and improves overall engine performance.

What’s the Best Way to Prevent Air Leaks in Intake Components?

To prevent air leaks in intake components, you should regularly inspect all gaskets, boots, and hoses for cracks, tears, or looseness. Even small leaks can cause lean running conditions, so replace worn gaskets and cracked boots promptly. Don’t overlook tightening clamps securely and applying gasket sealant where needed. Remember, neglecting these steps can make it seem like your carburetor needs more tuning, but fixing leaks is often the key.

How Often Should I Clean or Service My Carburetor?

You should clean or service your carburetor at least once a year or whenever you notice symptoms like rough idle, stalling, or difficulty starting. If you use your equipment frequently or operate in dusty conditions, consider cleaning it more often, such as every 3 to 6 months. Regular maintenance includes inspecting jets, passages, and gaskets, as well as using fresh fuel and stabilizer to prevent gumming and debris buildup.

Why Does My Engine Stall After Warming up Even With a Clean Carb?

Your engine stalls after warming up because the carburetor isn’t adjusting properly, often due to incorrect mixture settings or vacuum leaks. Even with a clean carb, if the idle or main mixture screws are too lean, the engine won’t get enough fuel once warm. Check for air leaks around intake gaskets, and consider tuning the mixture screws or inspecting the carb for worn parts to fix the issue.

Conclusion

If your engine only runs on choke, you’re risking a disaster that could turn your vehicle into a useless hunk of metal. Don’t let dirt, leaks, or misadjusted parts turn your ride into a paperweight. By regularly inspecting, cleaning, and maintaining your carburetor, you’ll prevent small issues from snowballing into catastrophic failures. Keep your engine breathing easy, perform routine checks, and avoid turning your daily drive into a frustrating, smoke-belching nightmare!